联系我们

18560023440

王经理:18560023440

地址:山东省德州市齐河县经济开发区齐众大道7号-2车间

业内资讯

业内资讯

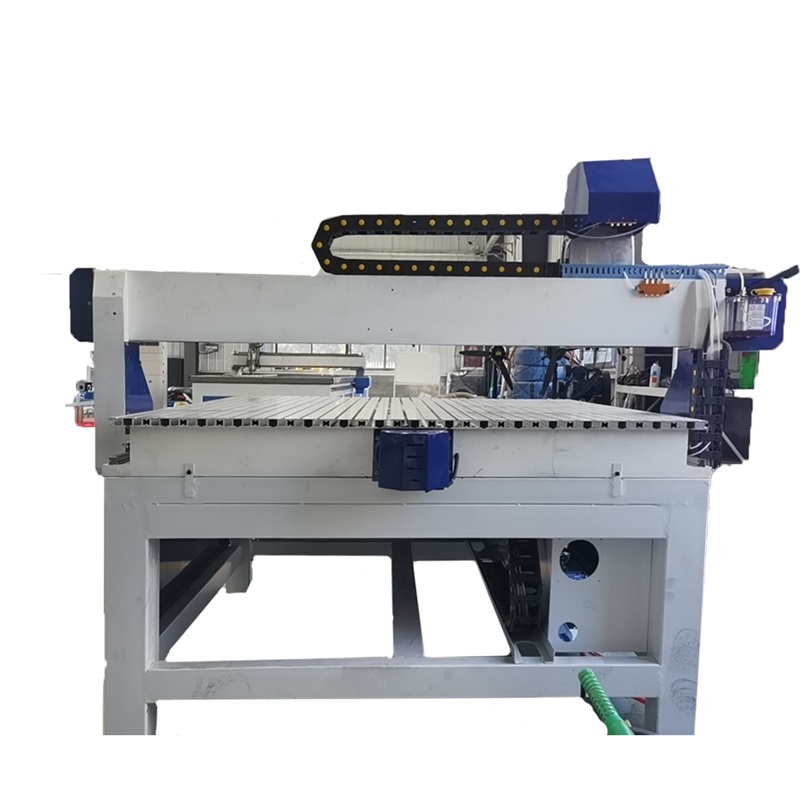

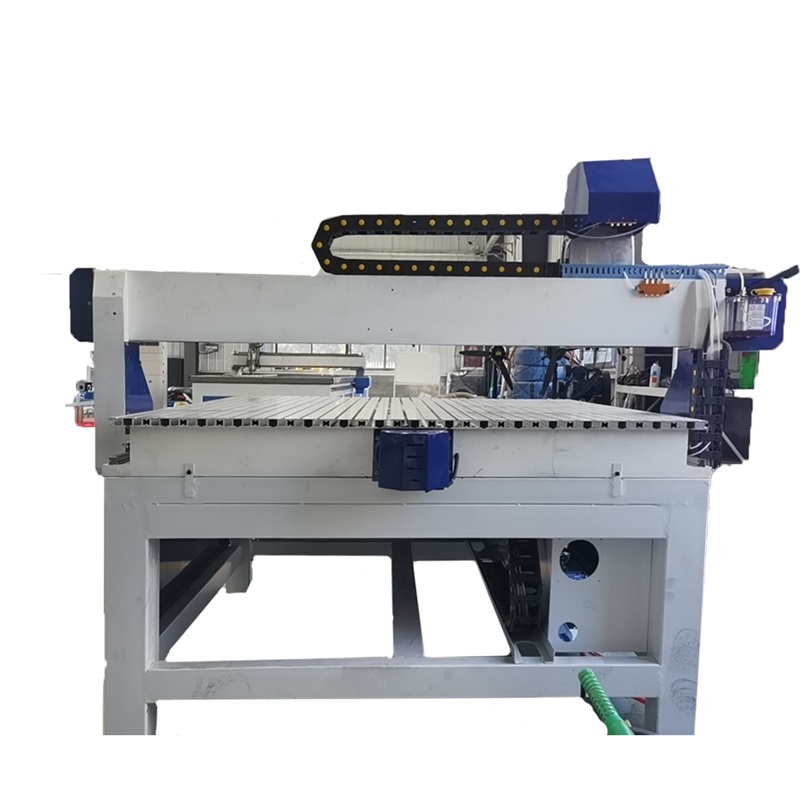

四轴雕刻机的外圆磨削有什么不同?

来源:http://www.jmycnc.com 时间:2021-02-19

四轴雕刻机的无心外圆磨与普通外圆磨的不同之处?无心外圆磨它没有头架和尾架,而是由托板和导轮支持工件,用砂轮进行磨削。无心研削法它是由磨削砂轮,调整轮和工件支架三个机构构成,其中磨削砂轮实际担任磨削的工作,调整轮控制工件的旋转,并使工件发生进刀速度,工件支架在磨削时支撑工件。无心外圆磨床生产率较高。多用于大量生产,易于实现自动化

What's the difference between high efficiency centerless cylindrical grinding and common cylindrical grinding of four axis engraving machine? Centerless cylindrical grinding has no headstock and tailstock, but supports the workpiece by supporting plate and guide wheel, and grinds with grinding wheel. Centerless grinding method is composed of grinding wheel, adjusting wheel and workpiece support. The grinding wheel is actually responsible for grinding. The adjusting wheel controls the rotation of the workpiece and makes the workpiece feed speed. The workpiece support supports the workpiece during grinding. The productivity of centerless cylindrical grinder is high. It is used in mass production and easy to realize automation

普通外圆磨削

General cylindrical grinding

四轴保丽龙雕刻机的普通外圆磨削利用工件两端的孔,把工件支承在磨床的头架及尾座间,磨削时工件在主轴带动下作旋转运动,砂轮作横向进给。

The common cylindrical grinding of 4-axis styrofoam engraving machine uses the center holes at both ends of the workpiece to support the workpiece between the center of the head frame and tailstock of the grinder. During grinding, the workpiece rotates under the drive of the spindle, and the grinding wheel feeds transversely.

无心外圆磨削

Centerless cylindrical grinding

无心外圆磨它没有头架和尾架,而是由托板和导轮支持工件,用砂轮进行磨削。无心研削法它是由磨削砂轮,调整轮和工件支架三个机构构成,其中磨削砂轮实际担任磨削的工作,调整轮控制工件的旋转,并使工件发生进刀速度,工件支架在磨削时支撑工件。无心外圆磨床生产率较高。多用于大量生产,易于实现自动化。

Centerless cylindrical grinding has no head frame and tail frame, but supports the workpiece by supporting plate and guide wheel, and grinds with grinding wheel. Centerless grinding method is composed of grinding wheel, adjusting wheel and workpiece support. The grinding wheel is actually responsible for grinding. The adjusting wheel controls the rotation of the workpiece and makes the workpiece feed speed. The workpiece support supports the workpiece during grinding. The productivity of centerless cylindrical grinder is high. It is used in mass production and easy to realize automation.

无心外圆磨削较普通外圆磨削的特点

Characteristics of centerless cylindrical grinding compared with common cylindrical grinding

连续加工,无需退刀,装夹工件等时间短,生产率高。

Continuous processing, no tool withdrawal, short clamping time and high productivity.

四轴雕刻机的无心外圆磨床工件靠外圆在定位机构上定位,磨削量是工件直径上的余量,故砂轮的磨损、进给机构的补偿和切入机构的重复定位精度误差对零件直径尺寸精度的影响,只有普通外圆磨床的一半,不需打孔,且易于事先上、下料自动化。

The workpiece of centerless cylindrical grinder of four axis engraving machine is located on the positioning mechanism by the outer circle, and the grinding amount is the allowance on the diameter of the workpiece. Therefore, the influence of grinding wheel wear, feed mechanism compensation and repeated positioning accuracy error of cutting mechanism on the diameter and dimension accuracy of parts is only half of that of ordinary cylindrical grinder, and there is no need to drill the central hole, and it is easy to load and unload materials in advance.

四轴雕刻机的磨削表面易产生奇数次棱圆度,如较大时往往会造成测量尺寸小于实体尺寸的错觉,而影响装配质量和工作性能。 机床调整较复杂、费时,每更换不同直径的工件就需冲调整托架高度,与距离及有关的工艺参数。故调整技术难度较大,不适宜小批及单件生产

The grinding surface of four-axis engraving machine is easy to produce odd degree of edge roundness. If it is large, it often causes the illusion that the measured size is less than the maximum solid size, which affects the assembly quality and working performance. The adjustment of the machine tool is complex and time-consuming. It is necessary to adjust the height of the bracket, the distance and the related process parameters when changing the workpieces with different diameters. Therefore, it is difficult to adjust the technology, which is not suitable for small batch and single piece production

- 上一篇:双工序开料机企业好双工序开料机

- 下一篇:三工序雕刻机与木工雕刻机区别