联系我们

18560023440

王经理:18560023440

地址:山东省德州市齐河县经济开发区齐众大道7号-2车间

业内资讯

业内资讯

雕刻机使用前后需要做哪些工作?

来源:http://www.jmycnc.com 时间:2021-01-07

雕刻机的操作是有学问的,简单的启动开机大家都会,那只不过是动动手指的事情,但是您一定不知道在您按下按钮的那一刻起整部机器经过了哪些运作,不如让我们不做一个详细的了解,对您机器的保养和寿命都是有好处的。

The operation of engraving machine is learned. We all know how to start it. It's just a matter of moving your fingers. But you don't know what operation the whole machine has gone through when you press the button. It's better for us not to do a detailed understanding, which is good for the maintenance and life of your machine.

一、电脑方面

1、 Computer

定期查杀病毒,但注意工作时不可以打开防毒程度,小心干扰。定期清理机箱灰尘,注意机箱的散热,小心灰尘过多引起工控卡出错。定期整理磁盘碎片,优化电脑系统。

Check and kill the virus regularly, but pay attention not to open the anti-virus level when working, and be careful of interference. Clean up the dust of the chassis regularly, pay attention to the heat dissipation of the chassis, and be careful of the industrial control card error caused by too much dust. Regularly defragment the disk and optimize the computer system.

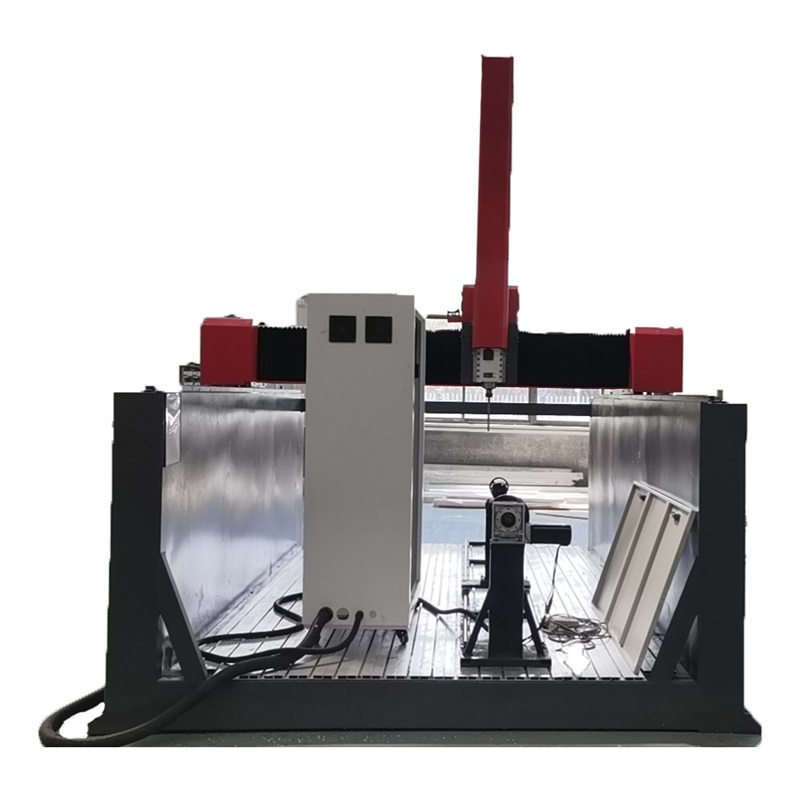

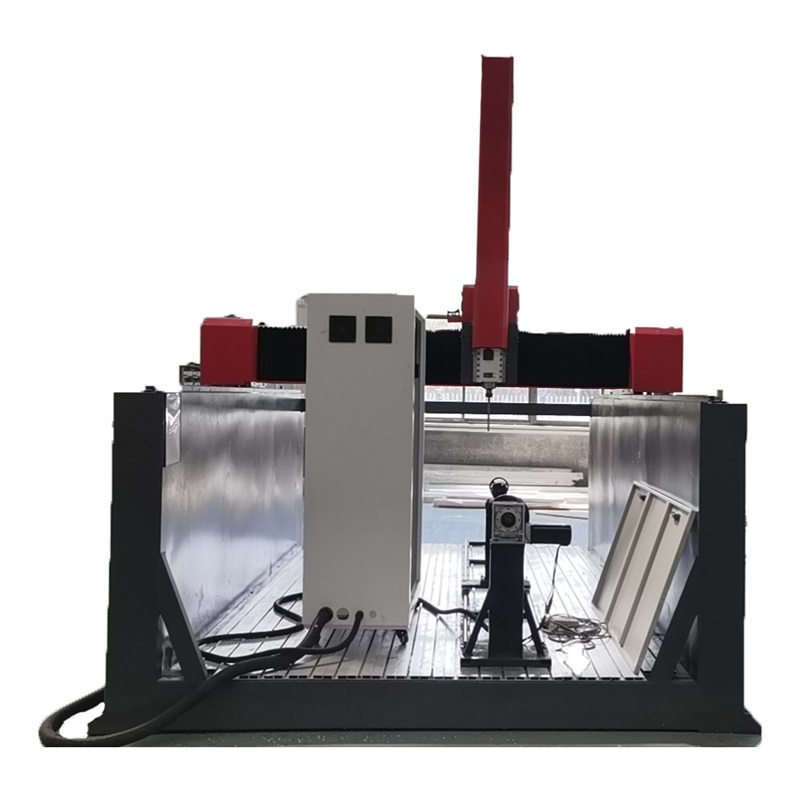

五轴保丽龙雕刻机

Five axis styrofoam engraving machine

二、清理

2、 Clean up

定期清理工控箱,灰尘时电路板的杀手。定期清理丝杠,防止丝杠上粘有异物,丝杠在设备中很重要,他决定了机器的精度,而且丝杠在传动过程中也起重要作用。

Regularly clean the industrial control box, dust is the biggest killer of circuit board. Regularly clean the lead screw to prevent foreign matters sticking on the lead screw. The lead screw is very important in the equipment, which determines the accuracy of the machine, and the lead screw also plays an important role in the transmission process.

工作完了应及时清理台面,这就给木工雕刻机下次工作提供了方便。清理导轨及导轨旁边的材料屑,以防止因碎屑干扰导致机器在工作过程中出现卡机。

After the work, the table should be cleaned in time, which provides convenience for the next work of woodworking carving machine. Clean the guide rail and the material scraps beside the guide rail to prevent the machine from jamming during operation due to the interference of scraps.

三、上油

3、 Oiling

加完油后慢速来回走动,保证润滑油能够均匀加到导轨与丝杠上。机器若长期不用,应定期加油空走,以保证传动系统的灵活性。

After adding oil, walk back and forth slowly to ensure that the lubricating oil can be evenly added to the guide rail and lead screw. If the machine is not used for a long time, it should be refueled regularly to ensure the flexibility of the transmission system.

清理干净导轨与丝杠,可用布不脱毛把导轨和丝杠上的油污和材料屑清理掉。因气温较低,可把导轨和丝杠都加机油,加防冻机油。加油周期为每月两次,也就是每两周加一次油。

First of all, clean the guide rail and lead screw, and use cloth to clean the oil and material debris on the guide rail and lead screw. Due to the low temperature, the guide rail and lead screw can be added with engine oil and antifreeze engine oil. The refueling cycle is twice a month, that is, once every two weeks.

四、温度

4、 Temperature

机器不用时,若室温较低更好倒出水箱里的水,防止冻裂水箱与水管。保证操作间环境温度,木工雕刻机达到室温,少工作人员也不会很冷。查看所加油标准适用温度,少达到低温度。

When the machine is not in use, if the room temperature is low, it is better to pour out the water in the water tank to prevent the water tank and water pipe from cracking. Ensure that the operating room temperature, wood engraving machine to room temperature, at least the staff will not be very cold. Check the applicable temperature of the refueling standard, and at least reach the low temperature.

温度对于木工雕刻机的影响不是很大,但由于用户给丝杠加黄油,冬季也忘了清理,导致每次开机运行不开,有的工作室气温很低,虽然加了机油,可还是冻上了,机器运行不起来。

The influence of temperature on woodworking engraving machine is not very big, but because the user adds butter to the screw and forgets to clean it in winter, the machine can't run every time. The temperature of some workrooms is very low. Although the engine oil is added, it is still frozen and the machine can't run.

五、冷却水

5、 Cooling water

有条件可以使用防冻液冷却。注意环境温度,小心因水温过冷而造成水箱与水管冻裂。冷却水为主轴电机正常工作的必要条件,若冷却水过脏会对电机造成严重伤害,保证冷却水的清洁及水泵的正常工作。注意水位,绝不可使水冷主轴电机出现缺水现象,使电机热量不能及时导出。

If possible, antifreeze can be used for cooling. Pay attention to the ambient temperature, be careful of the water tank and water pipe crack caused by the water temperature is too cold. Cooling water is a necessary condition for the normal operation of the spindle motor. If the cooling water is too dirty, it will cause serious damage to the motor, so as to ensure the cleaning of the cooling water and the normal operation of the water pump. Pay attention to the water level, never make the water-cooled spindle motor lack of water, so that the motor heat can not be exported in time.

- 上一篇:2030保丽龙雕刻机应用及性能介绍!

- 下一篇:雕刻机产生雕刻不圆滑的原因是什么?