联系我们

18560023440

王经理:18560023440

地址:山东省德州市齐河县经济开发区齐众大道7号-2车间

业内资讯

业内资讯

四工序开料机的配置都有什么?

来源:http://www.jmycnc.com 时间:2020-12-11

1、四工序开料机配置双工序排钻数控开料机是两个主轴加一个排钻包,一个主轴负责开料,一个主轴负责划槽,然后配合5+4钻包进行垂直孔操作,实现多个孔位同时打孔的功能。

1. The four process cutting machine is configured with double process row drilling. The CNC cutting machine is composed of two spindles and a row drilling package. One spindle is responsible for cutting and the other is responsible for slotting. Then, it cooperates with the 5 + 4 drilling package for vertical hole operation, so as to realize the function of drilling holes at multiple positions at the same time.

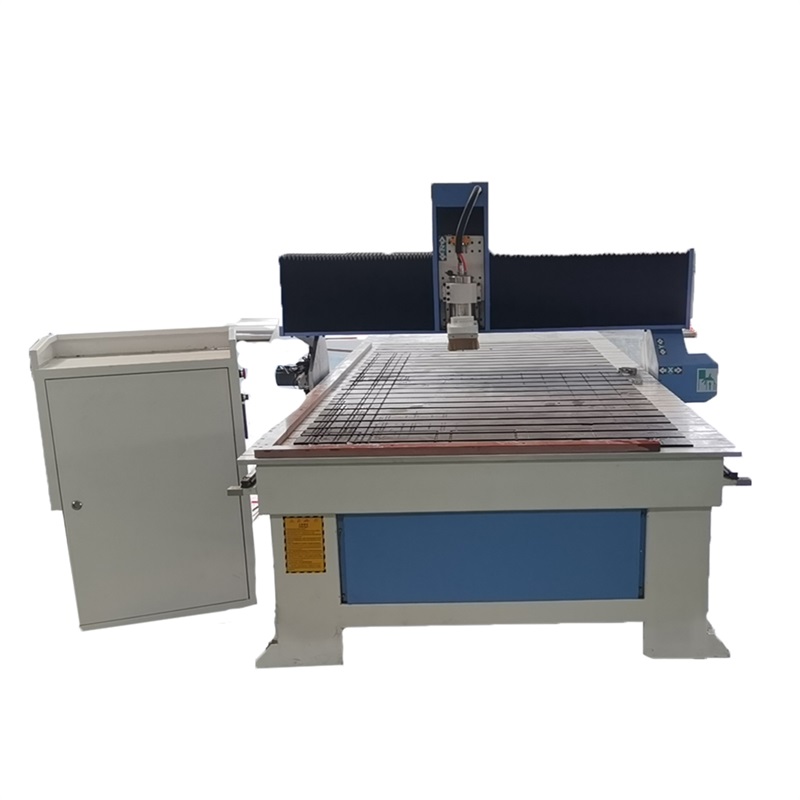

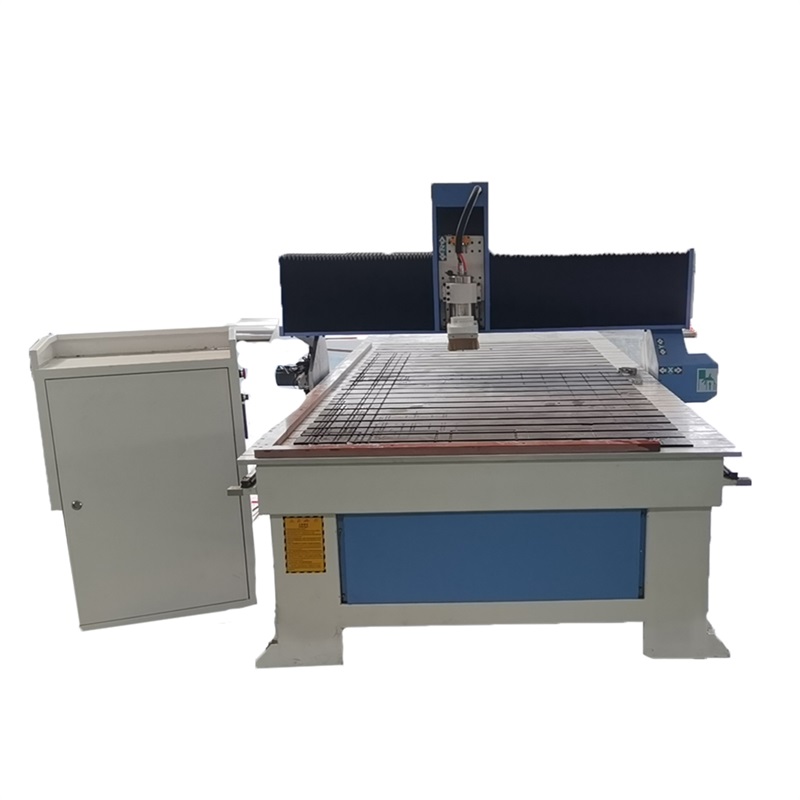

四工序开料机是由四个主轴组成,通过气动换刀,可以安装不同的家具实现板式家具开料、打孔、开槽、橱柜门板铣型等工艺。

The four process cutting machine is composed of four spindles. Through pneumatic knife changing, different furniture can be installed to realize panel furniture cutting, punching, slotting, cabinet door plate milling, etc.

双工序数控开料机

Double process CNC cutting machine

2、四工序数控开料机支持四把刀自动换刀功能,与双工序排钻开料机相比较,无法多钻头同时打孔,做柜体加工效率比双工序排钻低很多。

2. Compared with the double process row drilling and cutting machine, it can't drill holes at the same time, and the processing efficiency of cabinet body is much lower than that of double process row drilling.

3、四工序开料机用途广,既可以做柜体又可以加工门板,对于中小型橱柜、衣柜厂来说,本身产量不是很高,但是可以一机两用,而且预算比较低,那么选择四工序开料机是比较划算的。双工序排钻数控开料机主要用于柜体的加工,打孔速度比四工序开料机要快的多。

3. Four process cutting machine is widely used. It can be used for cabinet and door panel. For small and medium-sized cabinet and wardrobe factories, its output is not very high, but one machine can be used for both purposes, and the budget is relatively low. Therefore, it is more cost-effective to choose the four process cutting machine. The double process row drilling CNC cutting machine is mainly used for the cabinet body processing, and the drilling speed is much faster than the four process cutting machine.