联系我们

18560023440

王经理:18560023440

地址:山东省德州市齐河县经济开发区齐众大道7号-2车间

新闻资讯

新闻资讯

四工序开料机和是四工序雕刻机是一种设备吗?

来源:http://www.jmycnc.com 时间:2020-12-02

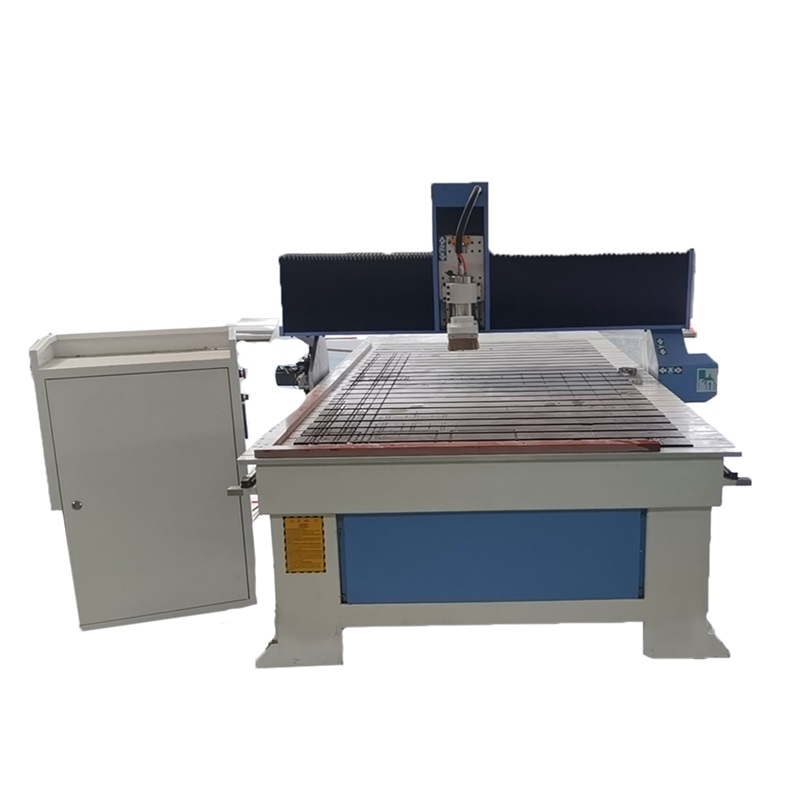

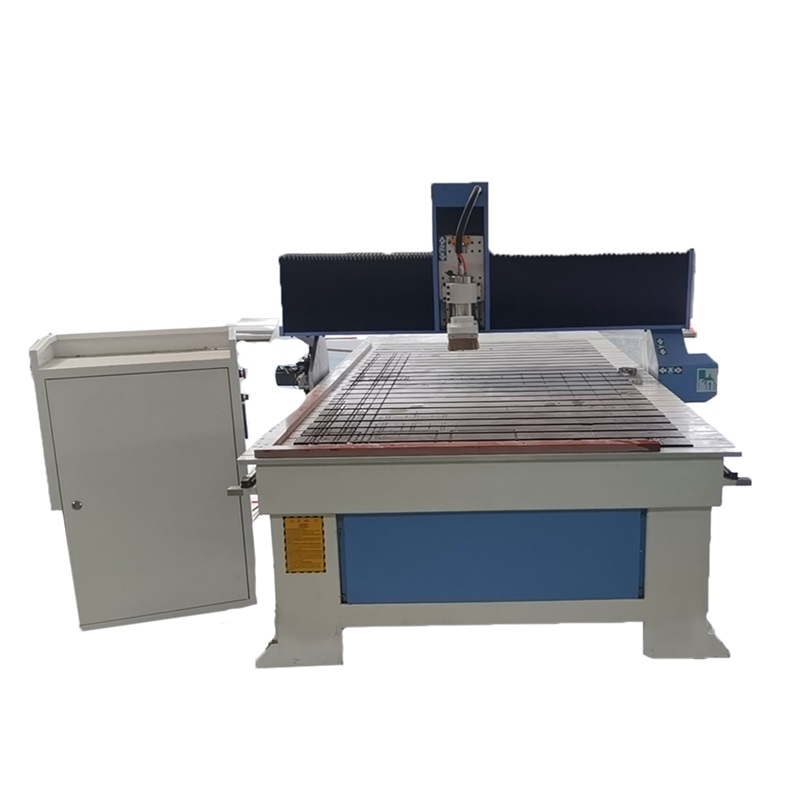

四工序开料机和是四工序雕刻机本身都是干木工用的机械设备,但是四工序开料机主要是针对客户在制造板式家具的时候用来钻孔,开槽,开料的。四工序雕刻机主要是用在做简单柜门,做铣形,雕刻机,镂空的工艺。四工序开料机所用的配件主要都是高配耐用性比较强,四工序雕刻机都是国产配置,耐用性差。

The four process cutting machine and the four process engraving machine are both mechanical equipment for dry woodworking, but the four process cutting machine is mainly used for drilling, slotting and cutting materials when manufacturing panel furniture. Four process engraving machine is mainly used to make simple cabinet door, milling, engraving machine and hollowing out. The accessories used by the four process cutting machine are mainly high configuration, and the durability is relatively strong. The four process engraving machine is all domestic configuration, with poor durability.

对于这两款数控开料机的相同点来讲,二者都是用来加工板式家具、衣柜、橱柜的板材,包括切割、铣槽、打孔三种功能。打孔的主要口径为直径5mm、直径8mm、直径10mm、直径15mm四种情况。两款板式家具开料机的床身结构也是相同的,都是重型T形台面,整体床身经过二次退火加工,由高精度数控金属加工进行铣面。

For the same point of the two CNC cutting machines, they are used to process panel furniture, wardrobe, cabinet board, including cutting, milling slot, drilling three functions. The main diameter of drilling is 5mm, 8mm, 10mm and 15mm. The bed structure of the two panel furniture cutting machines is the same, both are heavy-duty T-shaped table, and the whole bed is processed by secondary annealing and milled by high-precision CNC metal processing center.

就不同点而言:,通过字面意思我们就可以看出双工序排钻数控开料机多一个排钻功能,而四工序数控开料机仅仅是四个主轴。其主要功能区别就是,在进行板式家具、衣柜、橱柜板材打孔的时候,双工序排钻开料机利用排钻包,可以实现多个孔位同时打孔的功能,不用停机换刀,提高了打孔的工作效率。

In terms of the differences: first of all, through the literal meaning, we can see that the double process row drilling CNC cutting machine has one more drill row function, while the four process CNC cutting machine is only four spindles. The main function difference is that when punching the panel furniture, wardrobe and cabinet board, the double process row drilling and cutting machine can realize the function of multiple hole positions drilling at the same time, without stopping the machine to change the cutter, which improves the working efficiency of drilling.

而对于四工序数控开料机来讲,如果您用直径8mm的刀,而板材上需要打不同规格的孔,那么你就需要停机换刀或者扩槽,但是无论哪种方式,效率都是相对较慢的,而且一次只能打一个孔。结论就是双工序排钻开料机打孔速度更快,孔位精准度更高。第二,在拆单软件方面,双工序排钻数控开料机需要额外的一个功能,所以在方面也要比普通的四工序数控开料机的要贵一些。

For the four process CNC cutting machine, if you use a 8mm diameter cutter and need to drill holes of different specifications on the plate, you need to stop the machine for tool change or slot expansion. However, no matter which way, the efficiency is relatively slow, and only one hole can be drilled at a time. The conclusion is that the drilling speed is faster and the hole position accuracy is higher. Second, in terms of the single software, the double process row drilling CNC cutting machine needs an additional function, so in terms of price, it is more expensive than the ordinary four process CNC cutting machine.